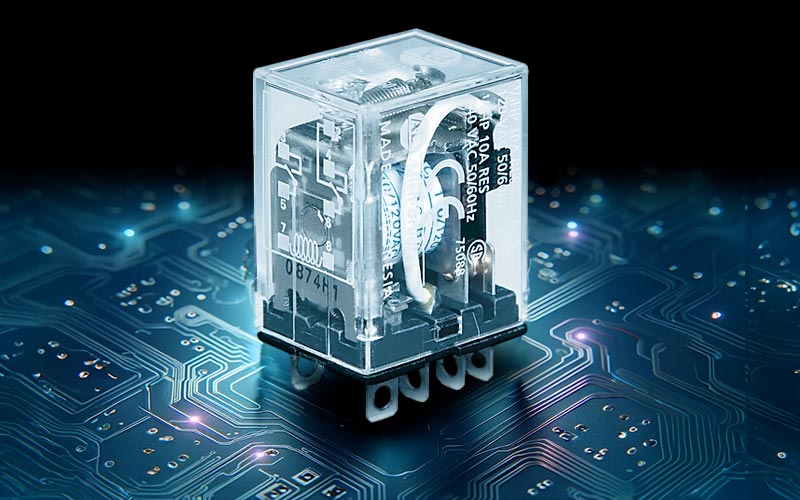

Ice cube relays are a popular type of electromechanical relay, named for their compact, cube-shaped design. These relays are a standard choice in various electrical applications due to their small size and versatility. Please catch our maintenance tips at the end of this article!

Key Features and Characteristics:

Compact Design: Ice cube relays are designed to be small and modular, making them ideal for use in applications where space is at a premium.

Electromechanical Operation: Like other electromechanical relays, ice cube relays consist of a coil and a set of contacts. The application of an electrical current to the coil generates a magnetic field that moves an armature, causing the contacts to change their state (open or closed).

SPDT or DPDT Configurations: Ice cube relays are available in Single-Pole, Double-Throw (SPDT) or Double-Pole, Double-Throw (DPDT) configurations. SPDT relays have one set of normally open (NO) and one set of normally closed (NC) contacts, while DPDT relays have two sets of each.

Contact Ratings: Ice cube relays come with various contact ratings, allowing them to handle different levels of electrical current and voltage. This makes them versatile for a range of applications.

Applications:

Ice cube relays are used in:

Ice cube relays are used in:

- Industrial automation

- Control systems

- HVAC (heating, ventilation, and air conditioning)

- Lighting control

- Other instances where a small, versatile relay is needed

Mounting and Installation:

Socket Mounting: These relays are often designed to be mounted on sockets, allowing for easy replacement or removal during maintenance. The socket provides a secure connection and simplifies the installation process.

DIN Rail Mounting: Many ice cube relays are designed to be mounted on DIN rails, which are standard mounting rails used in industrial control panels.

Plug-In Types: Some ice cube relays feature plug-in designs, allowing for easy installation and replacement by simply plugging the relay into a matching socket.

Coil Voltage: Ice cube relays are available with different coil voltages, enabling users to select relays that match the control voltage of their system.

Final thoughts…

To ensure the reliable operation and longevity of ice cube relays, electricians should regularly inspect them for physical damage, clean the contacts as needed, match the coil voltage with the system’s control voltage, and periodically test their functionality.

It’s also important to replace worn relays, ensure proper mounting, avoid overloading, protect them from environmental factors like moisture and dust, and clearly label them for easy identification during maintenance or troubleshooting.

Related articles: